Flush Wood Door Edges

Flush wood doors can be made in a variety of methods including 3-ply and 5-ply, among other constructions. While the internal components such as the core, stiles, rails, and cross bands are important features that impact performance attributes, the face veneer is what end users see every day. Architects and designers focus heavily on this aesthetic component of the door as it is a key design element in buildings.

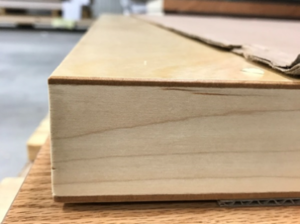

Obviously when the door is closed, the face is all that is seen from the inside and outside of the room. When the door is open, the vertical edges become visible on both the lock and hinge side. Typically, vertical edges (stiles) are either exposed wood matching the face veneer or mill option compatible with the face veneer. Veneer edge bands are also used to match the face veneer to produce a finished edge with no exposed crossband. Both manufacturing options are recognized as acceptable construction by WDMA and AWS, the two quality standards used by wood door manufacturers. With a typical flush wood door, these vertical edges show the stiles and crossbands which vary in color from each other and the face veneer. Although this effect is acceptable for many applications and expected in commodity doors, this appearance is not always anticipated by the end user and may cause a disruption in the aesthetic intent of the opening itself, and building as a whole, when a decorative opening is specified.

However, there are solutions for this. Stain colors can minimize the variance in view. Darker stains will help the components blend better if using MDF crossbands, while HDF crossbands blend better with lighter stains. If the design intent is to appear as one solid piece of wood, as it is in many decorative applications with high-end veneers, use of edge-bands will hide the internal components completely. The edge-bands will match the face veneer and receive the same stain so as to provide the continuous aesthetic look that was designed and accepted by architects, designers and building owners. Most wood door manufacturers understand this demand and offer edge-banding as standard practice on high grade veneers.

So what can you do to ensure your flush wood doors deliver to the jobsite as expected? Know how your product fits in with the application. If this is a commodity door, the edges are likely not a concern. If the doors are going into a high end office space, design is probably a key factor and the edges should match the face. Contact your wood door manufacturer when in submittal or estimating phase and be sure that matching wood stiles or edge-banding is specified on the request, or you have chosen the best stain option. If edge-banding is not included, you can always add this on as an option. Additionally, architects can specify openings this way to ensure this detail is not missed along the way. This is recommended for projects where decorative openings are required.

For more information on flush wood doors, as well as stile and rail and laminate doors, visit www.assaabloywooddoors.com. For a guide to decorative products, including doors and hardware, visit www.thegooddesignstudio.com.

No comments yet - you can be the first!